|

(click the images to enlarge)

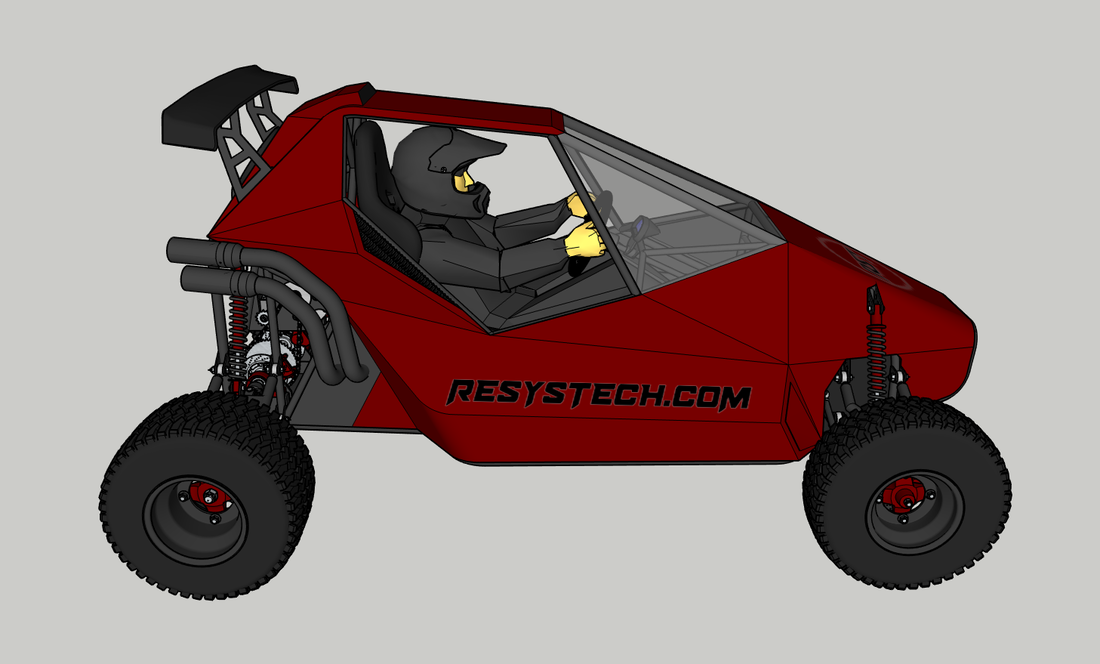

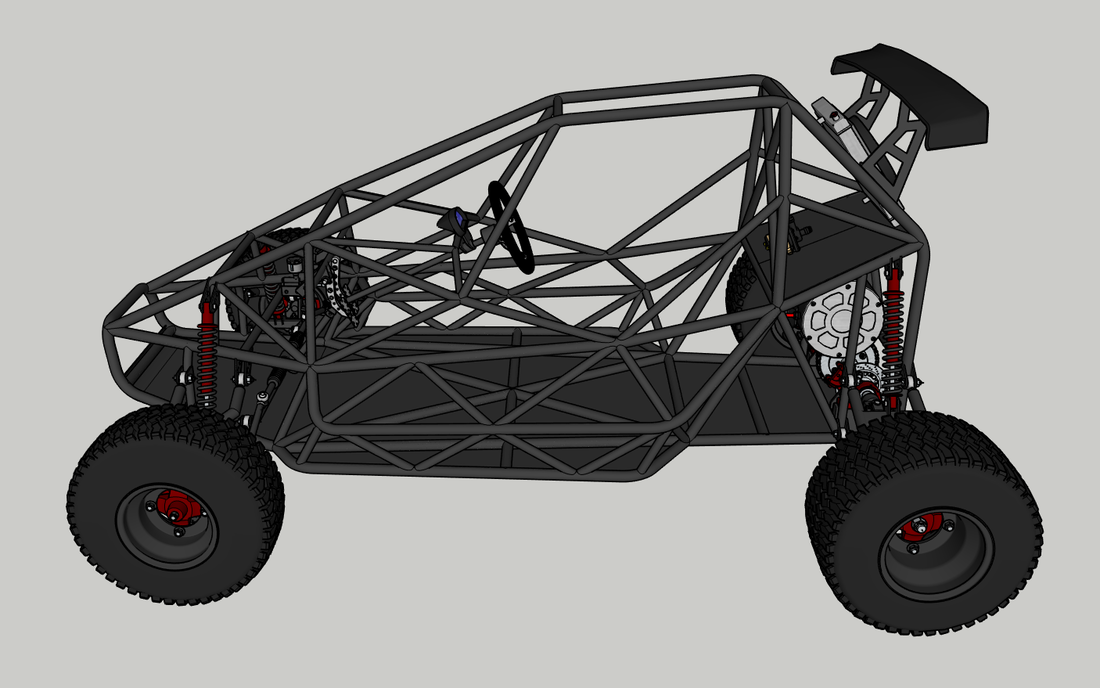

I've finished the crosskart CAD, for the most part. There are still a few things missing like the wheel fenders, coolant lines, etc, but there's enough detail for you to get a pretty good idea of what the end goal is for this project. If you haven't seen the previous posts about this crosskart, I recommend checking them out. They detail the motor, controller and battery specs (w/ source links) that will make up the 55 kW (73 hp) drive system.

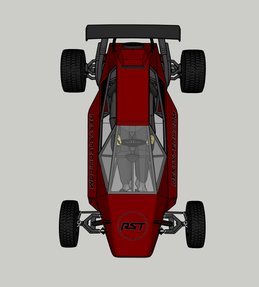

The chassis will be made with 1.25" and 1" diameter x 0.12" thick wall DOM steel tubing. I incorporated a bit more bracing than most crosskarts would have because of the extra weight from the batteries and I want to make sure it's rugged enough to take a beating in the trails.

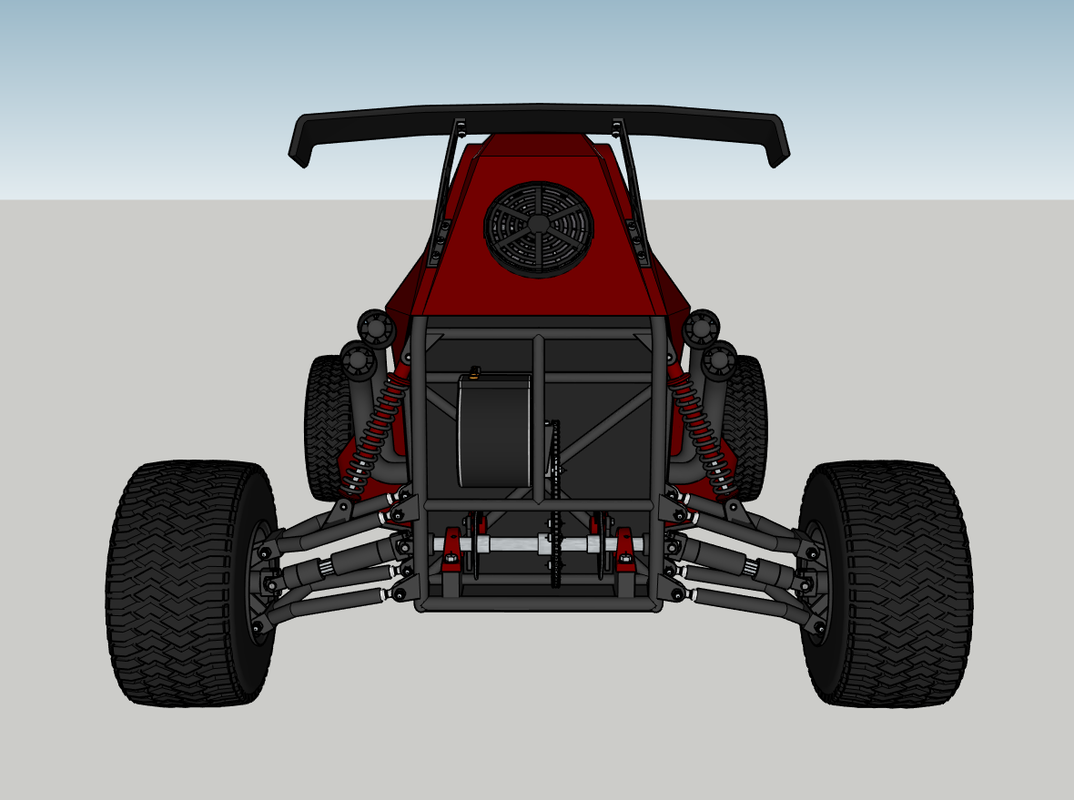

I chose independent double wishbone suspension for the front and rear wheels. The lower control arms are arched to provide more ground clearance (total 10"), and the upper arms are a bit shorter than the lower arms so they'll cause a slightly negative camber as the 15" coil-over shocks and 22" wheels travel upward and provide some added anti-roll stability when cornering. Max wheel travel for the front and back will be roughly 8", on par with most.

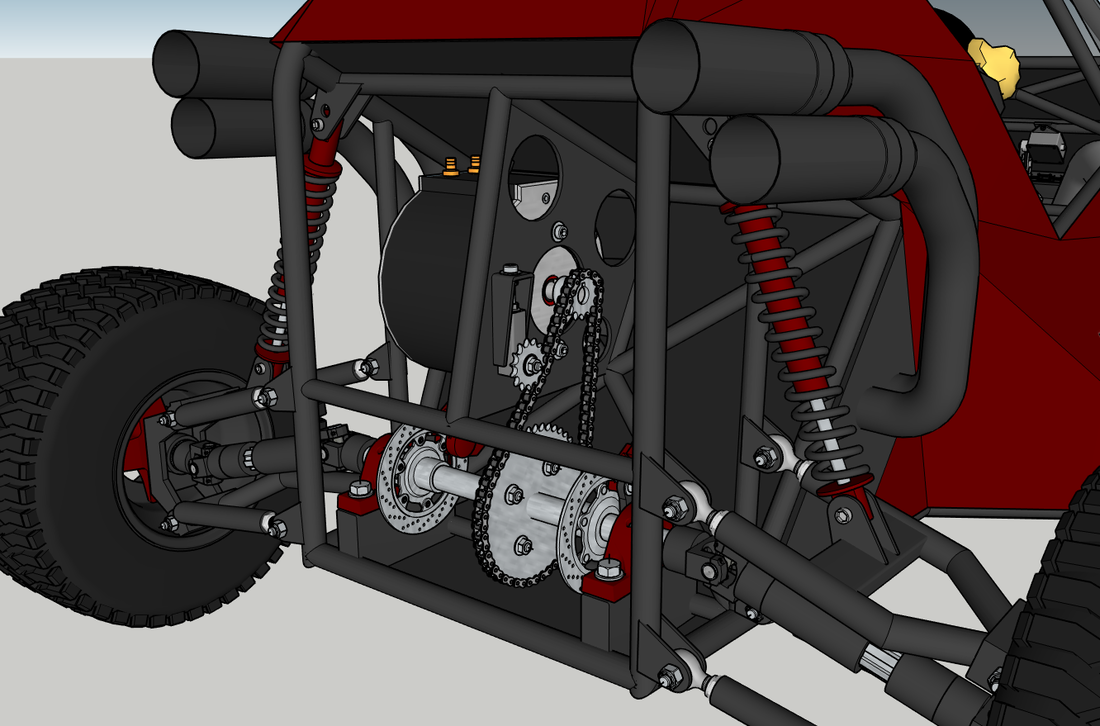

In the CAD you'll see that I have u-joints and telescopic PTO shafts making the connection between the rear wheels and the 1.25" dia. stainless steel solid axle mounted in the center, but I'm probably going to modify a couple of atv cv axles to use instead to help cut down on weight and increase transmission efficiency (cv axles are more efficient than standard u-joints). I'm not sure what I'm going to use for gearing yet, but it will either be 3:1 or 4:1 between the driven and drive sprockets. A 520 motorcycle chain will connect them, and 1.25" pillow blocks will bolt to the chassis and hold the axles in place. Of course, there's also a chain tensioner mounted beside the ME1616 motor to take up any slack.

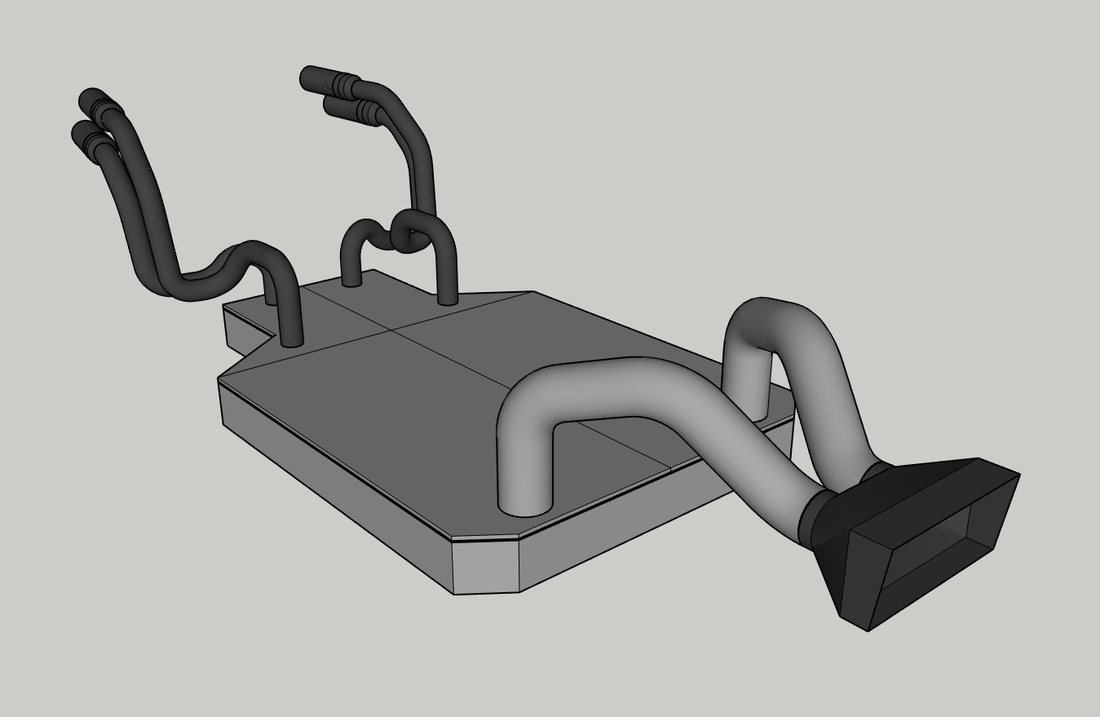

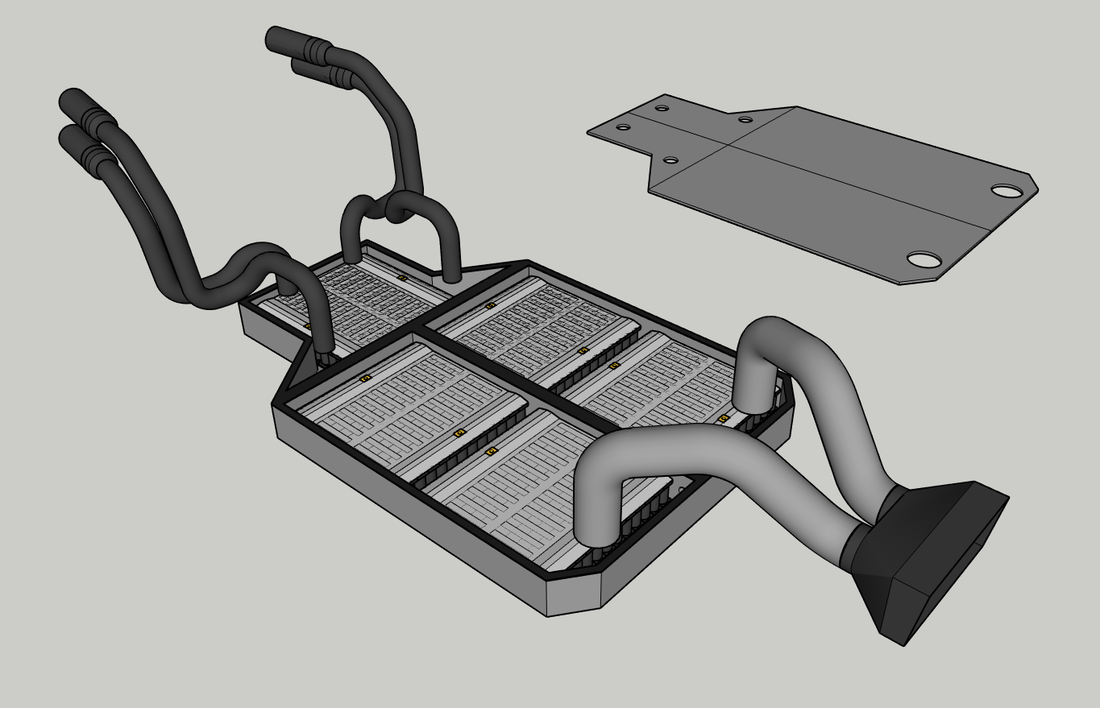

The exhaust pipes are actually just that - exhaust pipes, but for warm air being forced from the battery instead of burnt petrol fumes. As mentioned in the previous post, the battery will be overpowered for this application by more than 100A, which will cause it to operate cooler than it would if I build it to match the motor power specs. This allows me to get away with a simple forced air thermal management system for keeping the battery relatively cool.

Air will enter the system through the grill at the front of the crosskart, then travel around, between and over the cells from front to back and exit the exhaust pipes - each containing high flow inline blower fans that will turn on via a programmable digital thermostat when the temp demands to help compensate for the pressure drop in the system (caused by the drag/resistance the airstream will experience when travelling around the cells and duct cornering), and get the airflow moving faster when needed. All entry and exit points will have safeguards like drip loops to make water penetration to the battery impossible without completely submerging the crosskart in a water hole - which I would never do even if it weren't going to have an electric drive system.

I was originally going to braze together an aluminum box for the battery, but I've been considering using fiberglass panels and/or Coosa board. This would insulate the battery from the chassis and help keep me alive if anything crazy were to happen down there, and I think it would be easier to make it waterproof as well...with the exception of the TMS intake and exhaust ports, of course. I haven't brazed anything since high school over 20 years ago, so there's a pretty good chance that I would spend a lot of time chasing pin holes trying to make it watertight. But on the other hand, 90% of the box will have to be built in place due to space constraints (won't be able to get it in after the chassis' roll cage is welded in place). Either way, the cover will be bolted to the box perimeter in four pieces so that it can be removed at any time for servicing later. The seal between the covers an the box will be made with a continuous silicone gasket.

The radiator mounted on the back of the crosskart will provide cooling for the motor. Air will be forced into the radiator via the intake vents on either side of the cabin and the scoop on the roof, with help from a 12" fan. I avoided putting anything other than mechanical components in the front of the machine because I want a bit of a crumple zone there - if anything is damaged in an accident, I'd rather it just be tubing instead of other components like the rad or battery.

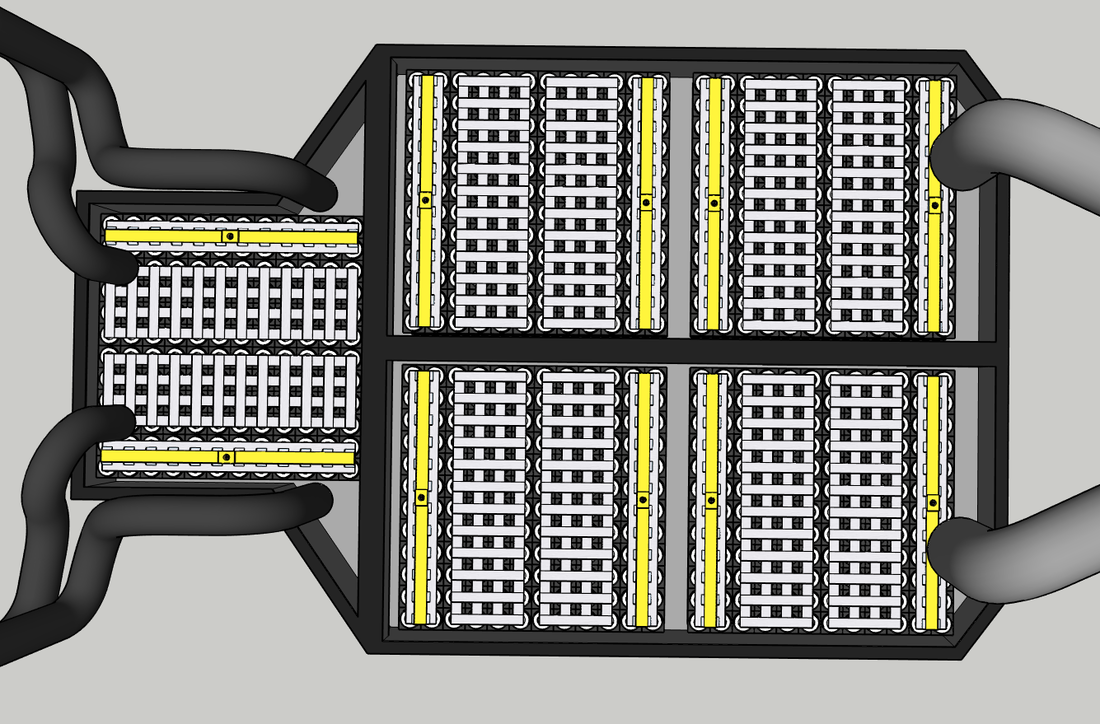

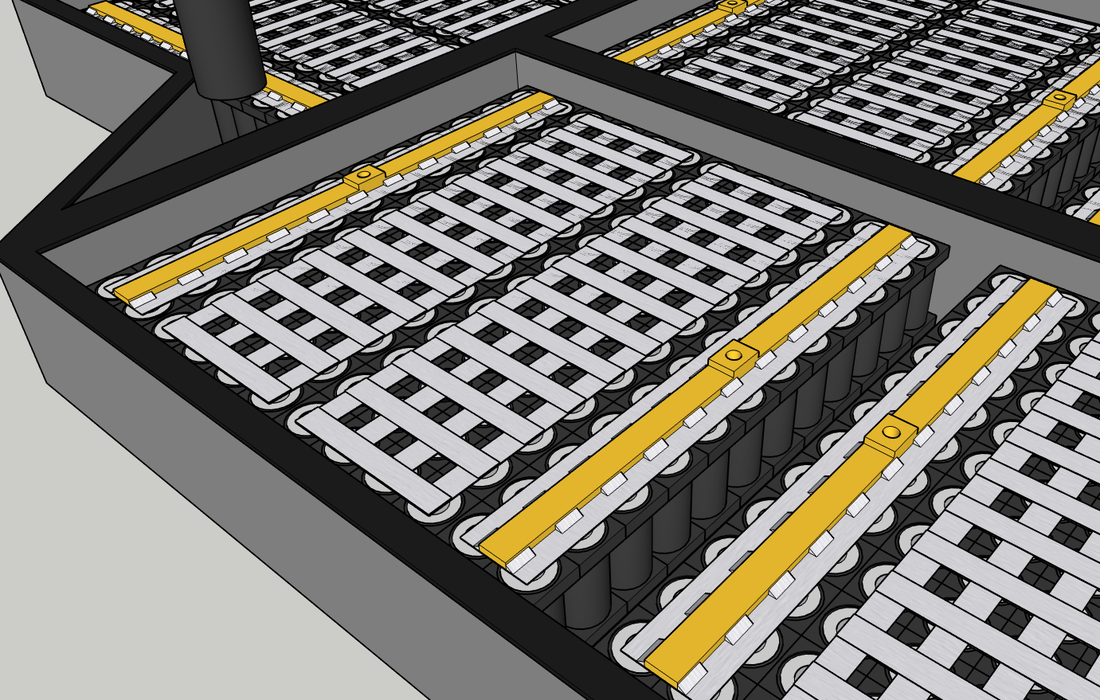

The battery will be made up of 5 series connected modules, each consisting of a 24P6S 5 Ah cell configuration to form a complete 24P30S, 120Ah/96V battery. I'll be using 0.2-0.3mm nickel strips to connect the cells, with every series connection in each module layered with enough strips to carry about 20% more current than the max continuous current that the 24P cells are capable of (ie: capable of carrying ~350-400A continuous). The first and last series connections for each module will be made with 1/4"x1" copper bus bars and nickel strips, with the copper being soldered to the nickel strips before they're spot welded to the cells to prevent overheating them with the soldering iron.

If desired, a person could incorporate two of the ME1616 motors to increase the power to 140+ hp and drive each rear wheel individually for better cornering on hard surfaces, or power the front wheels with the second motor to create a 4x4 machine, but you will need to use the more powerful 6 ah cells in the battery to handle it that load. That's it for now. As always, the plans will be available after the build has been tested. Tubing is on the way. I've got a small project to finish up for my grandparents which I might feature on the channel sometime next week to help fill in the gap between uploads. It's nothing spectacular but it is a useful device for seniors. More details on that and the crosskart build when the time comes.

9 Comments

Omkar Rahate

1/28/2021 10:04:04 am

I appreciate your efforts you are making to build unique crosskart

Reply

James Biggar

1/29/2021 11:27:48 am

Thanks for checking out the blog, cheers!

Reply

Michael harte

1/28/2021 06:27:20 pm

Hi James Biggar, Iv been subscribed for a couple of months now and I'm amazed at you skill and proffession. What engineering qualification do you have? I'm currently studying energy engineering it seem boring compared to your content

Reply

James Biggar

1/29/2021 11:35:59 am

Thanks. My 'engineering experience' consists of a an apprenticeship/journeyman carpenter certification, and 40 years of living on a homestead and learning to solve problems on my own. My father was also a heavy equipment mechanic and I picked up a lot of skills and mechanical knowledge from working with him growing up. In short, building experience with the right people will help you develop a plethora of skills that you won't get by boring yourself in university - HOWEVER, schooling is an important guide for using said skills properly. When you get out of university, take an apprenticeship and get your hands dirty building things under someone else's guidance. Doesn't matter what it is. Building house, cars, doll houses - as long as you're putting practical lessons to work in a tangible way and developing skill working different building materials, then that's all that matters. Get that combination under your belt and nothing will stop you.

Reply

David Lepage

2/1/2021 04:29:40 pm

Looking great James. Can hardly wait for the build and the plans to become available. I really want to build one of these and take a rip down to Martin Head. keep up the great work.

Reply

James Biggar

2/3/2021 03:09:30 pm

Thanks David!

Reply

Samuel Otieno

2/15/2021 03:07:07 am

Hi James.

Reply

Tim

3/21/2021 02:26:54 pm

Hey James,

Reply

Jon Murphy

3/24/2021 07:44:35 pm

Based on the dates I would guess this build is underway and I won’t hear from you in a bit. I’m curious about the 1 motor per rear wheel idea. Do you need a special controller that syncs the power to each wheel while going straight? Would it turn unintentionally without that? I guess while turning it doesn’t matter, each wheel will just put out whatever power and you won’t have the understeer problem.

Reply

Leave a Reply. |

AuthorJames Biggar Archives

March 2023

Categories |

RSS Feed

RSS Feed